Like any other machinery, automobiles are also complex and have a network of multiple parts working together to create an efficient operation. The user might not notice it, but an automotive duct is an indispensable piece of the complex machine that keeps an automobile efficient. From the HVAC ducts to under-the-hood ducts, automotive ducting is an integral part of keeping a vehicle running dependably. Ducts are passageways that facilitate the distribution of air throughout the system. In addition to acting as a channel for air return, air supply, and air exhaust, they help maintain the quality of the air and thermal comfort of the area. These are essential functions and failure of any can lead to fatal consequences.

Plastics Leading the Way Throughout:

Automotive ducts are mostly made of plastics such as Polyamide (PA), High Density Polyethylene (HDPE), Low Density Polyethylene (LDPE), Polypropylene (PP), and Polyphenylene Sulfide (PPS). The selection of the material is based upon the quality required and the nature of the application. For instance, PA and PPS are mainly used in making under-the-hood ducts, whereas PP, HDPE, and LDPE are mainly used to make HVAC (Heating, Ventilation, and Air Conditioning) ducts.

Plastic ducting has many advantages. Compared to metal ducts, plastic is lightweight which makes it easy to cut into different sizes, easy to install with fewer mounting points, and resistant to moisture caused by the air which passes through. Many such factors make plastics maintain their incontestable lead in the market for the coming few years.

Foam ducts, on the other hand, are packed with multiple benefits such as noise reduction, durability, hygiene, and they are of lighter weight than any other material. All such features make these ducts quite expensive.

According to Stratview Research, in the year 2020, plastic ducts cornered the market occupying more than four-fifth share of the market.

The different channels of ducting:

Automotive ducts serve different applications throughout the vehicle body. The engines need to be kept cool, and to maintain their temperature, hood scoops / under-the-hood ducts provide a limit-free supply of ambient air to the engine. Also, the interior has to be comfortable, and HVAC ducts (Heating Ventilation and Air Conditioning) manage the temperature within the vehicle.

The duct manufacturers are also seen to have application-wise dominance. For instance, Continental AG, MANN+HUMMEL Group, and Sogefi Group are the key players in under-the-hood ducts, whereas ABC Technologies, Rehau AG, and Nihon Plast Co. Ltd. are some of the key players in HVAC ducts.

Who doesn’t want a cleaner and pollution free atmosphere? Made with plastics (polypropylene or polyethylene plastics), HVAC ducts serve a major part in providing better air quality and maintain freshness within the vehicle. The changing climate conditions, virus-prone atmosphere, and air quality can be considered as the real movers for the demand for Automotive HVAC Ducts.

HVAC ducts are expected to remain ahead of the pack and are likely to register the highest CAGR during the coming five years, whereas under-the-hood ducts are likely to remain the second-largest application type over the same period.

Changing dynamics of the automotive ducts market:

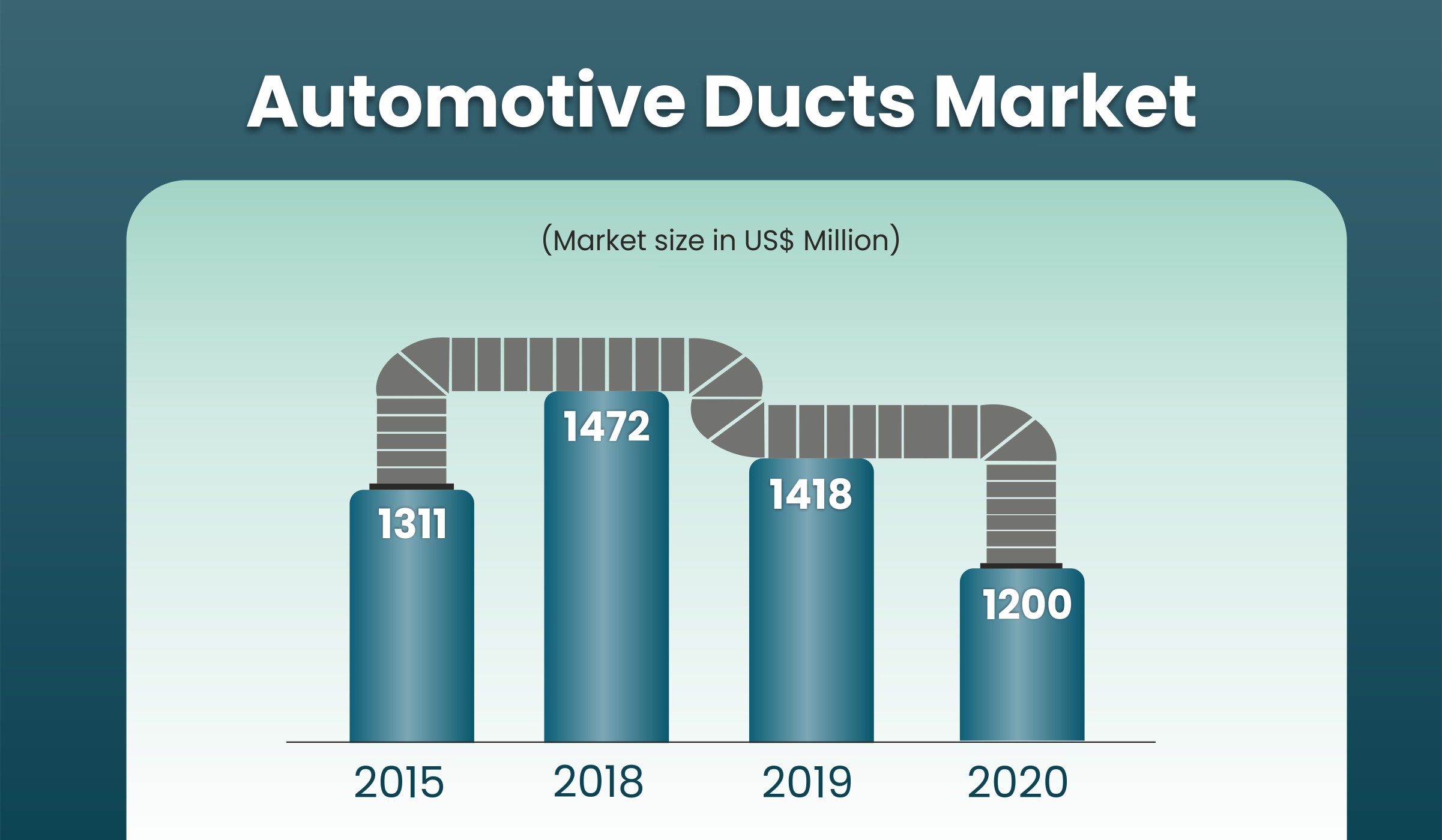

The Automotive Ducts market goes parallel with the automotive industry as the demand for automotive ducts principally depends on the automobile production. In 2019, the automotive industry experienced a major decline in vehicle production, mainly due to economic downturns in various countries. The industry was further slowed down by the COVID-19 pandemic facing more than -16% decline. As a result, the Automotive Ducts market steeped down to US$ 1200mn in 2020 from US $1418mn in 2019.

Countries like Germany, China, and The USA are known for their advanced technologies in the automotive industry, no doubt these countries together account for more than 60% share in the year 2020.

Now, as the global market slowly retaliates from the Covid19 crisis, our market experts envision a swoosh-shaped recovery in the automotive ducts market.

Most of the countries are spending funds to raise their vaccination rate and bring normalcy back. Most of the countries are on their due course to normalcy and it is expected that the automotive ducts market will recover at a healthy CAGR to reach a milestone figure of US$ 1.7 billion in 2026.

The future lies in material and technology advancement:

A passenger vehicle emits more than 4 metric tons of CO2 per year, according to EPA. It is no surprise that, transportation is responsible for major portion of the global CO2 emissions. Governments, specifically in the USA and Europe, are now imposing strict regulations on the automotive industries by demanding improved performance of new vehicles’ engines.

As the industry changes swiftly, the quest for improved solutions has led to the emergence of new and better products which offer reliability and durability.

For instance, in first week of November 2021, Ferraridebuted a new front brake duct system in Mexico, with the intent to tidy up the aerodynamic wakes, and smoothen the overtaking experience.

Development of high-temperature resistant ducts at a low cost, the development of ducts with single material construction, and the modern 3D printing technology are a few of the trends that are likely to affect the automotive ducts market.

Cadillac , a division of the American automobile manufacturer that designs and builds luxury vehicles, has announced that their 2022 manual transmission vehicles (Cadillac Blackwing V-series) will feature two 3D printed nylon HVAC ducts. By leveraging additive manufacturing, their team was also able to reduce costs and waste while developing the manual transmission.

Such developments are going to open doors of growth for the automotive ducts market.

Read more – Automotive Ducts Market